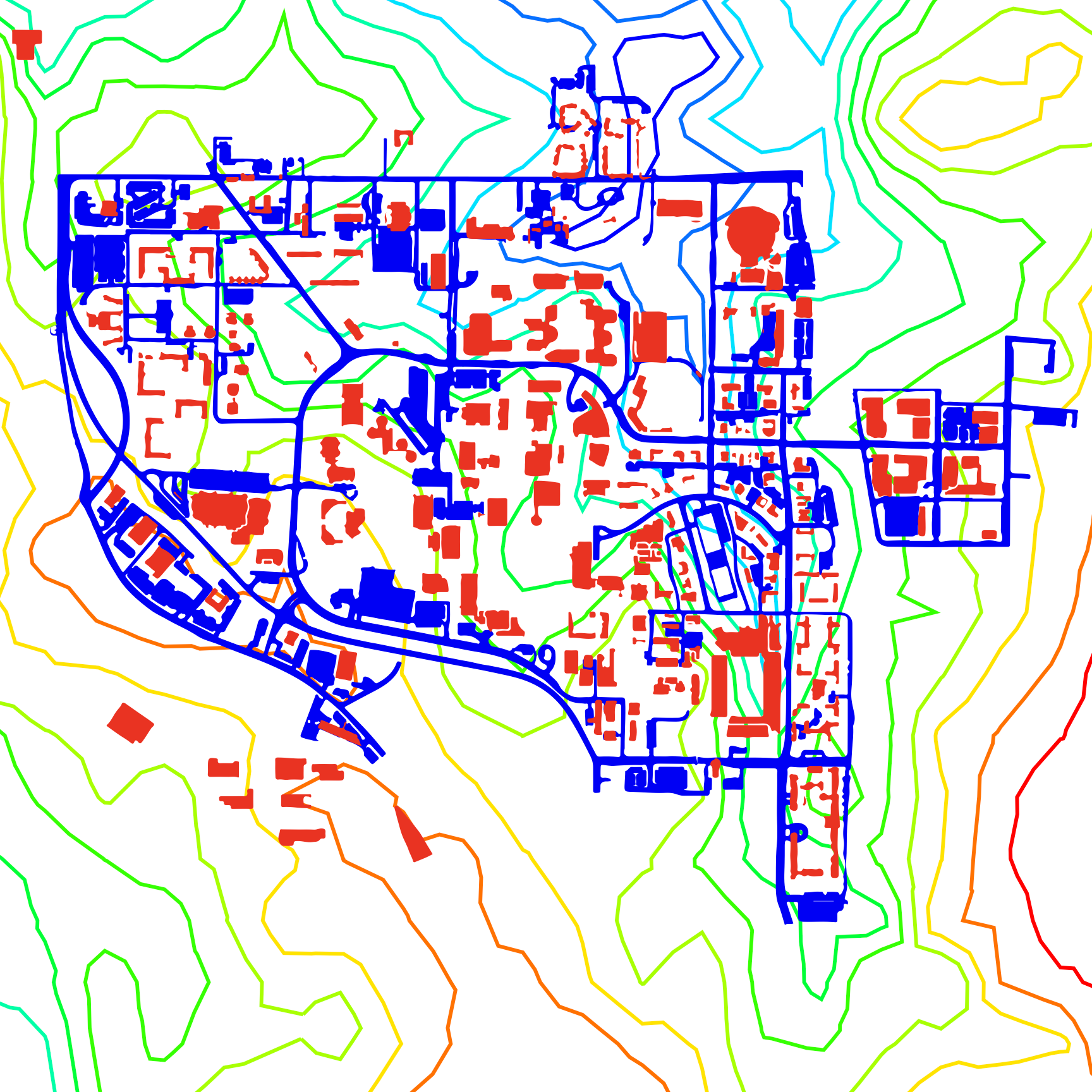

Georgia Tech Topographic Map

Make 10 is a class at Georgia Tech that challenges students to design, produce, and sell 10 of any project of their choosing. After constantly biking up the hills around campus, I wanted to visually see where they were and how I could avoid them.

Time Frame:

August 2023 - December 2023

Team:

Teddy Koutsoftas

Role:

Designer, Production Manager, Sales Lead

Skills/ Tools:

Adobe Illustrator, Laser Cutter, Shop Tools, Google Maps, Patience

Ideation + Prototyping

Building the map started with first making a template to laser cut using Adobe Illustrator. This required me to generate a topographic map of the area and a layout of all of the buildings and roads on campus.

Once this was refined, I was able to iterate with small scale chipboard models and determine the right amount of contour layers and how to emphasize the buildings over the roads with laser etching.

When this was honed in, I moved on to full scale plywood models. While cheap, when assembled the plywood felt very high quality. With these models I played with the title block, a potential frame, and how the final assembly would work.

Build

Once the final design was established, the most tedious and arguably the hardest part of the project began: the production.

A considerable amount of preplanning went into the design to make the production as quick as possible. I optimized the files to laser cut 4 layers at a time and only visible parts of the map were etched into the layer to avoid wasting time etching map that wouldn’t be visible. Regardless, it still took countless hours.

Once the layers were etched and cut, I assembled all the layers together with wood glue and brad nails. In the design of the file, I accounted for 4 dowels that would go through each piece. This helped immensely with the alignment of the assembly.

In total there were 12 maps made with 11 layers per map for a total of 132 layers that needed to be etched, cut, processed, and assembled. On average a group of 4 layers took 30 minutes to finish, and with assembly, this came out to around 2 hours per map. With these numbers plus material cost, I arrived at the cost of $60 a map.

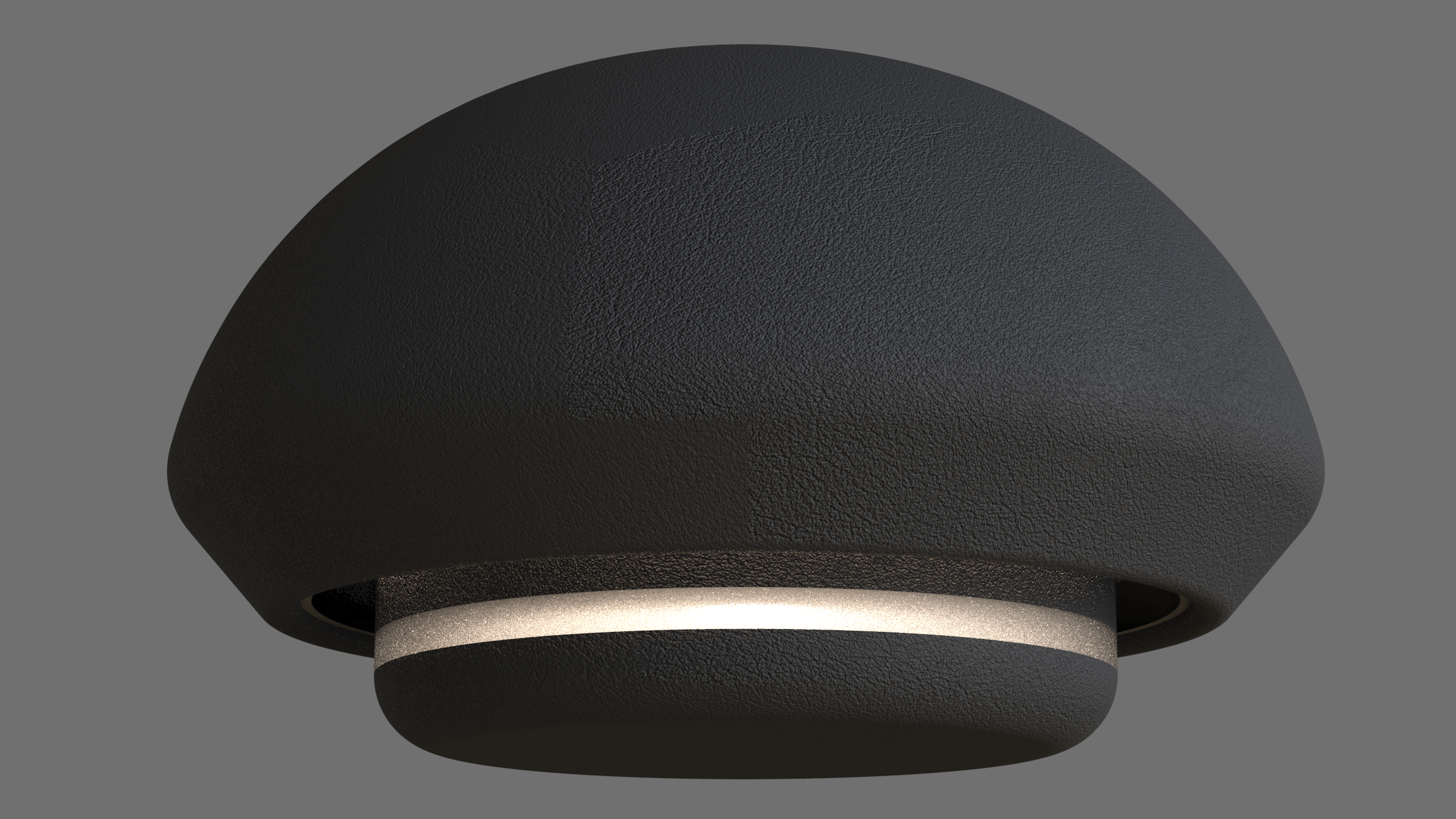

Final

In hindsight, I believe I could speed up production in a variety of ways and will continue to brainstorm if I plan to make more. Nevertheless, I am extremely proud of how the maps came out and that I was able to produce all of them. It was exciting to sell out at our end of the year show case and hear how they would be used for wall pieces, desk decorations, graduation and Christmas presents, and more.